It had a sleek, clean aerodynamic design. The turbojet engines, mounted in the roots of the wings, ran smoother and were quieter than piston engines. It was 50% faster than propeller aircraft of the era and had lower maintenance costs. With its pressurized cabin, it could fly above 30,000 feet, above most storms and turbulence and where the engines ran most efficiently. Large square picture windows gave passengers a spectacular view as they flew to their destinations.

The Comet was no match for the later Boeing 707. It carried only 36 to 44 passengers, and the airframe was designed to last only 10,000 flights. However, in the economic niche, it was intended for, the Comet could be profitable carrying only 43 percent of its capacity.

The Comet entered service on May 2, 1952, with British Overseas Airways Corporation (BOAC) on its route from London to Johannesburg. In its first year, the Comet carried 30,000 passengers. By 1953 the success of the Comet seemed assured. Many airlines, including Pan Am and Japan Airlines, were ordering the planned long-range higher capacity Comet 3.

A Comet 4

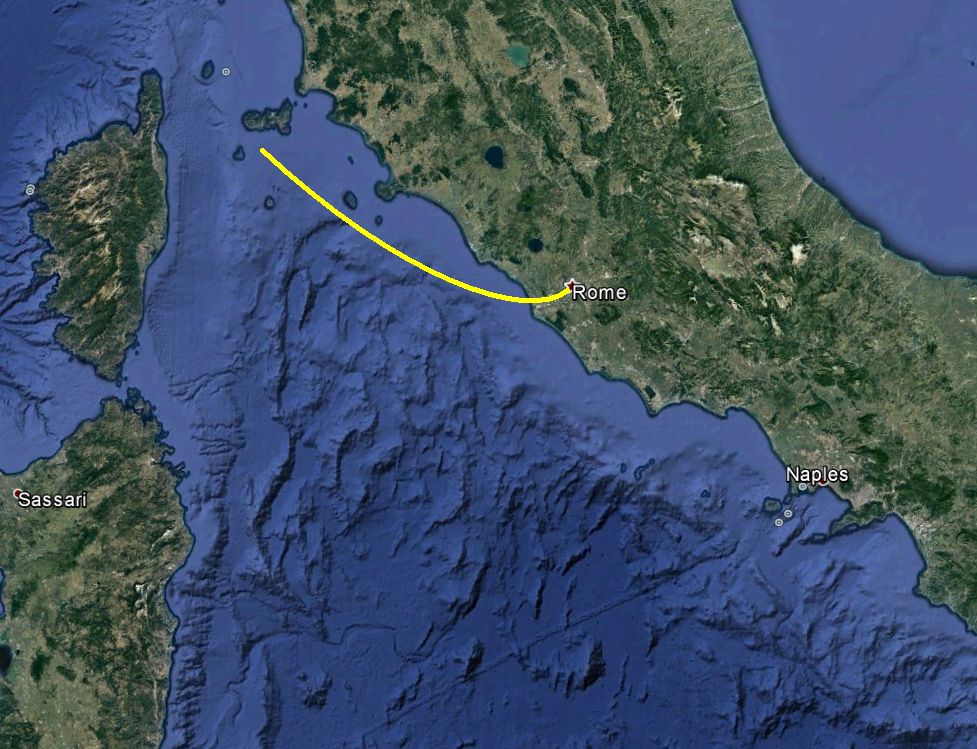

Then, on January 10, 1954, BOAC Flight 781 took off from Rome on its way to London. The aircraft was the oldest of the Comets in service and had flown 1,290 flights. 20 minutes after takeoff the Comet broke up in mid-air and crashed near the isle of Elba.

Routine radio communication was cut off mid-sentence, and there were no witnesses except for fishermen who saw wreckage falling into the Mediterranean.

A Convair XF2Y-1 Sea Dart breaking up after being overstressed. The de Havilland Comet breakups would have looked much like this.

The entire fleet of Comets was grounded for 10 weeks during the crash investigation. Without knowing the exact cause of the break-up, de Havilland made 60 modifications to the Comet “to cover every possibility that imagination has suggested as a likely cause of the disaster.” Possible causes addressed were control surface flutter, structural failure due to turbulence, engine fire, turbine blade failure and metal fatigue of the wing. Metal fatigue of the passenger cabin was not considered a likely cause.

The Comet re-entered service on March 23, 1954.

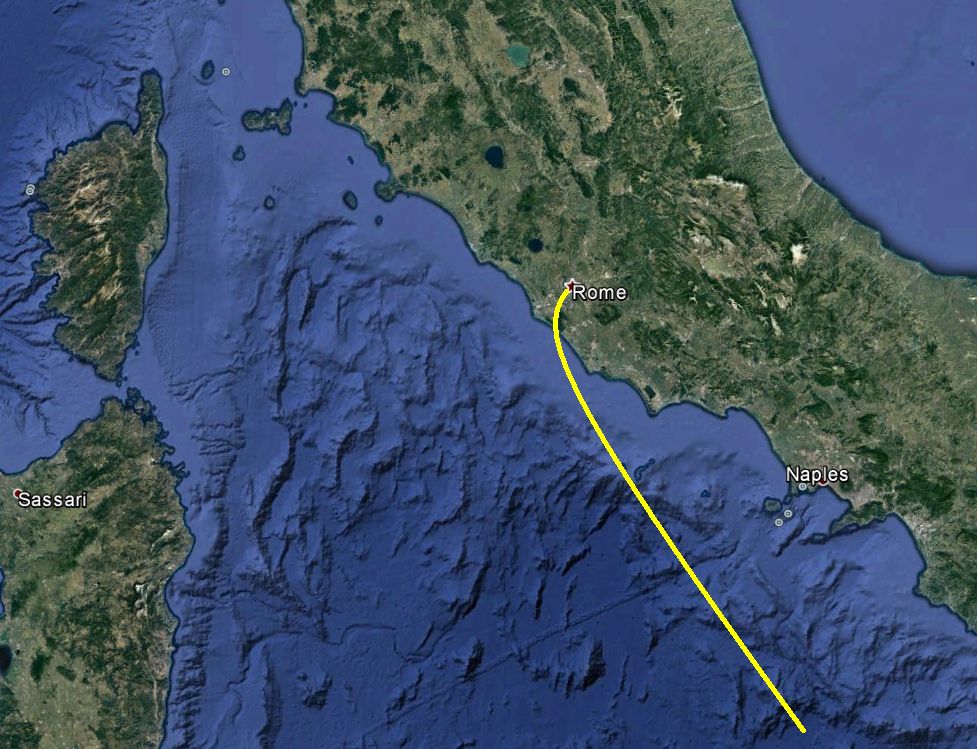

Then on April 8, less than three weeks after returning to service, South African Airways Flight 201 took off from Rome on a flight to Cairo, Egypt. This aircraft had flown 900 flights. A half-hour after takeoff while climbing through 35,000 feet, the Comet broke up and crashed into the Mediterranean south of Naples.

The Ministry of Transport withdrew the airworthiness certificate from the Comet.

Now, there were two crashes with unknown causes. Also, there had been another crash near Calcutta a year earlier. It was thought to have been caused by flight into a thunderstorm, but now it was looking suspiciously similar to the two Rome crashes. The wreckage off Naples was too deep to recover, so the investigators concentrated on recovering the wreckage of the first crash near Elba to find the cause of both crashes.

At the altitude where the Comet and modern commercial airliners fly the air is too thin to breathe. To make it possible to carry passengers the fuselage is sealed to create a pressure cabin. Extra air is pumped into the pressure cabin until the internal pressure is about the same as at 8,000 feet above sea level. This is about the lowest pressure where it is assured that no passengers will suffer ill effects. This puts about eight pounds per square inch of pressure into the pressure cabin. This may not sound like much, but it puts about 1,100 pounds of force on each square foot of the pressure cabin skin. The pressure cabin literally inflates like a balloon. It only expands about an eighth of an inch, but it does expand. This stores a certain amount of energy in the aircraft skin. However, much more energy is stored in the compressed air inside the pressure cabin. Should the skin rupture, the tremendous force on the skin from the compressed air inside can cause the rupture to expand until it rips the pressure cabin apart.

The question was, did the Comet pressure cabin rupture from pressurization and if so, why?

The main suspect was metal fatigue.

Metal fatigue is not when metal breaks from bending back and forth. Metal fatigue is the introduction and expansion of tiny cracks when the metal is flexed, but not so far that it will not return to its original shape. I can demonstrate this with a bag clip because plastic fatigues just as metal does.

As I open and close this bag clip, it flexes a tiny amount. You may not even be able to see it, but it is flexing. As I use the clip, it gets flexed over and over again. Eventually, this happens.

Tiny cracks form and the plastic eventually fails. The same thing happens to metal.

With each flight, the pressure cabin skin goes through a stretch and relax cycle. Over time, cracks form and eventually the skin will fail. This is why aircraft are retired and scrapped after a certain number of flights.

Now the question is, did the Comet skin fail sooner than the engineers expected. To test for this, they took one of the flying Comets and pressurized it over and over again to simulate thousands of flights. Engineers could then find out just how many flights the Comet pressure cabin could take before failure.

They didn’t want to do this by filling the cabin with compressed air. If they did so, the pressure cabin could be ripped to shreds when it failed. Instead, they put the aircraft in a water tank and pressurized it with water. Water is about 20,000 times less compressible than air; it is essentially incompressible. Water stores no significant energy when under pressure. Therefore, when the cabin ruptured there would be no compressed energy in the water to rip the cabin apart. Once the elastic energy in the stretched skin dissipated the rupture would stop, leaving the rest of the cabin intact for inspection and even repair for further testing.

The aircraft they tested had already undergone 1,230 flights. During tests, engineers simulated a further 1,830 flights before the pressure cabin ruptured. That’s only 3,060 flights. The Comet was designed to fly 10,000 flights before retirement. The Elba aircraft flew only 1,290 times. The Naples aircraft only 900. What went wrong?

The pressure cabin that they tested failed at the corner of the forward escape hatch. Shortly after the test, the part of the Elba aircraft containing the windows for the automatic direction finder antennas was recovered. The pressure cabin had ruptured at the corner of one of these windows showing the unmistakable signature of metal fatigue.

So that was it. Metal fatigue at the corners of the square windows. The stretching force is concentrated at the corners of the windows.

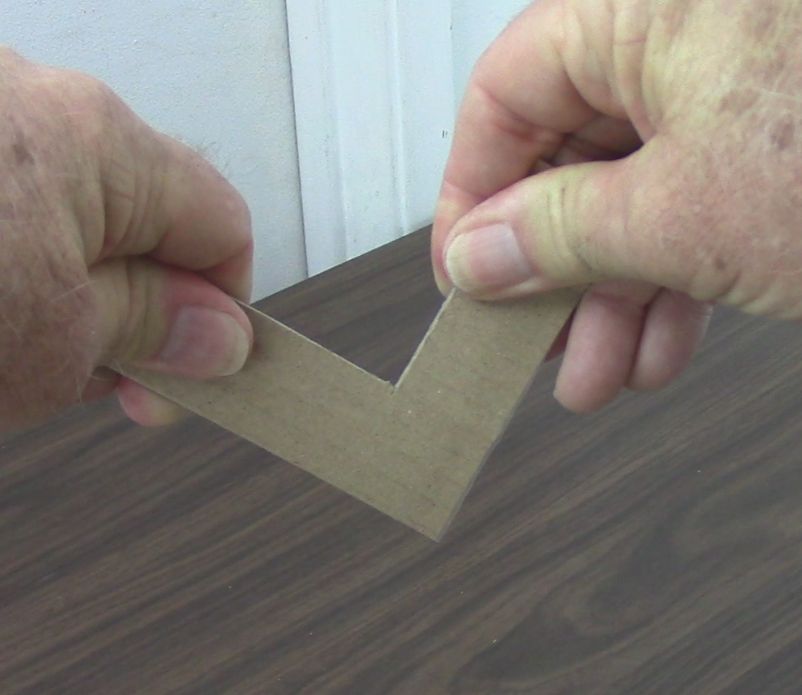

I can demonstrate this with this piece of cardboard. As I pull on it, you can clearly see that the force is concentrated at the square point where the arms come together,

and that is where it fails.

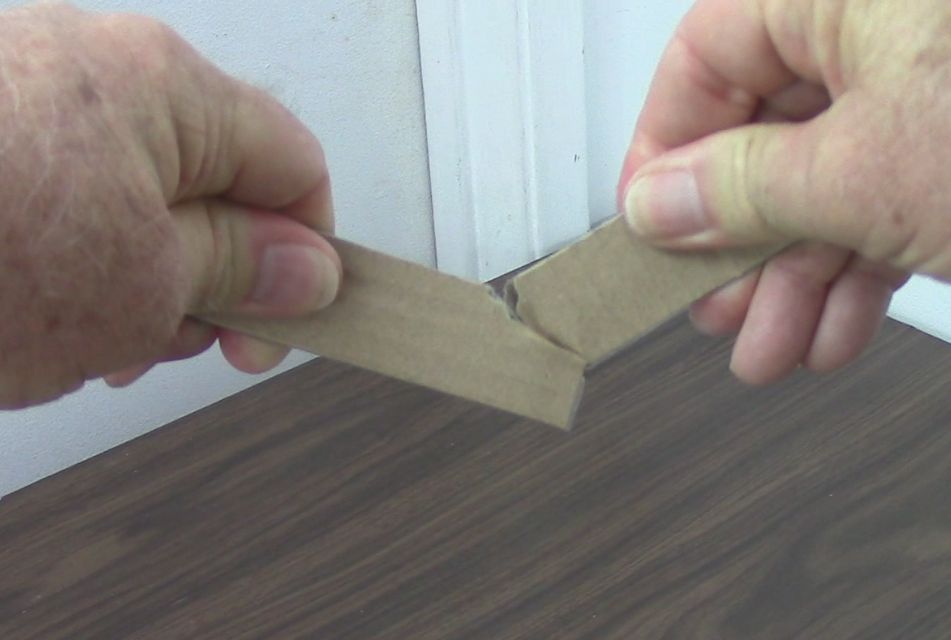

However, with this curved piece, the force is spread out over a large area. You can see that it is taking more force for the cardboard to fail.

It finally failed when I accidentally put a bit of twisting force on the left arm.

The square corner is where a rupture is most likely to start. However, if you round the corners, that force is spread out over a larger area; the force is not concentrated at a point. Which is why all airliners have round windows today.

And that’s the story of the de Havilland Comet. The square windows were its Achilles Heel. Metal fatigue caused cracks at the window corners that led to catastrophic failure of the pressure cabin, and that is why airliners today have rounded windows.

What you haven’t heard is that the engineers knew there would be a problem with the square windows.

De Havilland wanted large square windows to give the passengers a spectacular view. That was no real problem for the Engineers. They designed for it. They tested for it, and the Comet passed the tests.

Regulations required the pressure cabin to be designed to take 1.3 times the pressure experienced in flight. The de Havilland engineers designed the Comet to withstand 2½ times the expected pressure. Then they built a test pressure cabin and inflated it to 2 times flight pressure and repeated this 30 times. After that, they pressurized it to normal flight pressure, cycling it 2,000 times. Later, concerns about metal fatigue arose, so they decided to pressure cycle the pressure cabin until it failed. It withstood 16,000 more cycles, a total of 18,000 cycles, before failure. This was well above the planned 10,000 cycle life of the Comet. There was no doubt that the Comet was safe as far as pressurization was concerned. This is why metal fatigue of the fuselage was ruled-out in the original investigation of the Elba crash. So why were the Comets failing after as few as 900 flights?

What the de Havilland engineers didn’t understand at the time is that they shouldn’t have tested the same pressure cabin for both maximum pressure and number of flight cycles. When they overstressed the pressure cabin in the maximum pressure test, the metal went through a process called cold working. The initial stretching of the metal, especially at the corners of the windows, changed the crystalline structure significantly increasing its resistance to fatigue. Then, when they tested it for flight cycles, it passed with a wide margin. The production aircraft did not go through this process and tended to fail after around 1,000 flights.

The comet breakups were primarily caused by the square windows. However, it should not have been. They knew the square windows were problematic. They designed and tested for it. It should have failed the test. Then the engineers could have proceeded from there. However, because nobody understood that they shouldn’t have tested one airframe for overpressure then tested the same airframe for flight cycles, the mistake in the calculation was missed.

And that’s the true story of the de Havilland Comet, or so I thought before I came across this:

Using modern analysis not available at the time of the crashes, a team at the University of Birmingham concluded that the fatigue cracks were introduced when rivet holes were punched rather than drilled around the window cut-out areas. Such defects were not a problem with earlier aircraft because they were flown at lower altitudes and did not experience as much of a pressure differential. However, with the Comet these cracks grew until the pressure cabin ruptured and the aircraft was destroyed. All observed cracks in the pressure cabin emanated from the rivet holes, not the square cut-outs themselves. Other joints in the aircraft skin were glued. However, this was thought to be too difficult and expensive a procedure to use around the square cut-outs. Had the skin reinforcements around the windows been glued rather than riveted the failure might have been avoided. The University of Birmingham team concluded that:

So, the lesson learned with the De Havilland Comet was not so much the square windows as the airframe testing procedure. Had the engineers known to test the two aspects on separate airframes they would have probably discovered the construction flaw. All commercial airliners today have rounded windows, not because you can’t have square windows, but because round windows are less problematic.

Hmm, square windows

Nevertheless, the main contribution to the crash of the Comets made by the square windows was that it caused the builders to use rivets instead of glue in the construction of that part of the airframe. Had they glued the windows and doublers in place, the Comet’s history would probably not be so infamous.